|

We operate both automated machinery as well as

hand fed Scott tabbing equipment.

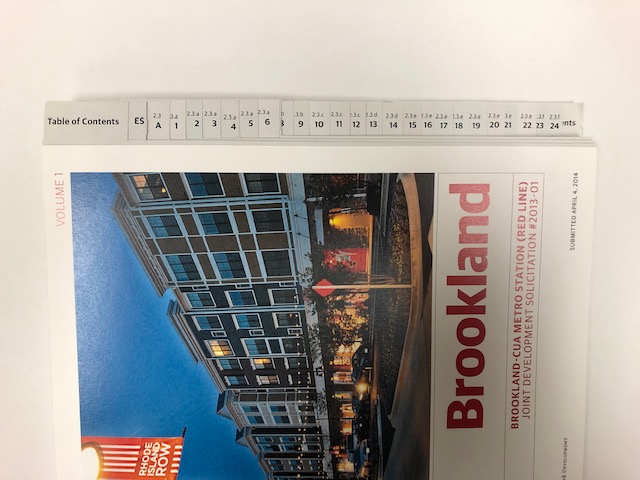

We have the ability to produce small and large

orders in a quick turn around.

We can do both square or rounded

tabs.

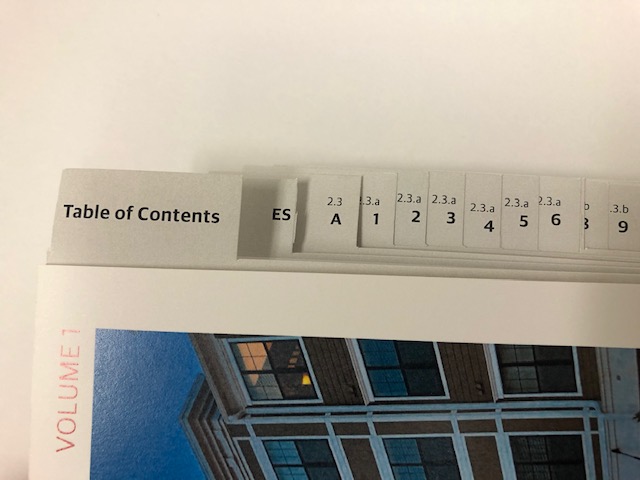

Quality:

All of our tab orders get the same quality whether they are for copy or printed jobs.

- When edge reinforcing, we trim the head and foot of the sheet to make

sure there is no extra material that may get jammed in you copy machine.

- We punch 3 holes instead of 3-hole

drilling. This minimizes the chance that the drilled out hole will get caught in your

copy machine.

- We collate with an index slip-sheet. This minimizes the

chance of an extra slip-sheet throwing off the collation order in your copy machine.

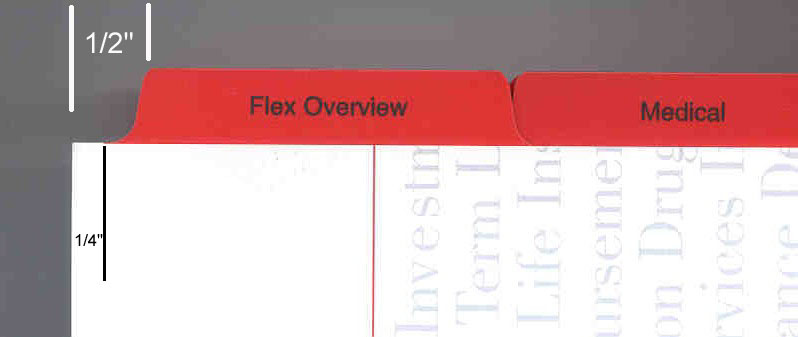

We do standard 1/2" round corner tab

extensions.

1/4" and 3/8" tab extensions available.

Click on the colors below or

click colors available to see all color.

Call or e-mail

to request our tab price list.

Laminate & Die

Cut Tabs (no body copy)

(Minimum sheet size of 5.5x6, maximum sheet size of 13x14)

See our multi color laminate image |

| Laminate & Die

Cut Tabs w/ Low Temperature Clear Laminate |

| Laminate & Die

Cut Tabs w/ Matte Finish laminate |

| Laminate & Die

Cut Tabs w/ Special Laser Print Laminate (Docutechable) |

| Laminate & Die

Cut Tabs with body printing |

| Die Cut only tabs |

| SGM Supplied Blank

Tabs, 110# or 90# White 9x11 Index, any cut (ask about A4 index) |

| Reinforce 1 side bind

edge, index stock |

| Reinforce 1 side bind

edge, bond or offset stock |

| Reverse or Standard

Collate |

| 3 Hole Drill |

Pre-Punch index stock, GBC, Wire-O, Plastic Spiral, Velo… |

| Shrink Wrap |

| Shrink Wrap with SGM

supplied chipboard |

| Slip Sheet between

sets |

Copier Tabs:

We manufacture copier tabs.

Paper stock is available in 90# index weight.

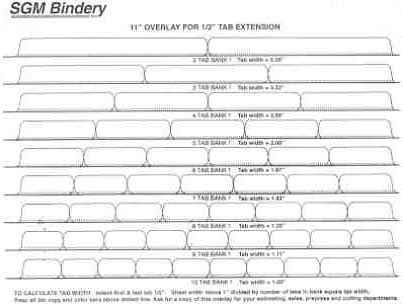

Bank set selection 5th cut.

Collated per your request.

1250 tabs per carton.

Ask about various bank selections, three hole punching, 110# index, laminating

the tab extension with special laser printable laminate.

Call for pricing.

Tab Printing:

We can print your index tabs.

Call for an estimate.

Tab Stripping:

-

When setting up your tabs, leave a

½" margin on the head and ½" margin on the foot.

-

On an 8.5x11 sheet after stripping

the margins, there is an 8.5 x10 area to work within.

-

Next, draw a line 7/16" from the

face, across the 10" dimension. This leaves you a 10.00" x 7/16" area to

print your tabs.

-

Now divide the 10" by the bank you

are stripping. For example, for a bank of 11, divide 10" by 11

resulting in .909". Thus you have a .909" by 7/16" area to print each tab.

-

Center and print.

-

Remember text or solid bleeds that

fall outside this area will not be cleaned off correctly when the tabs are

die-cut.

Tab Template

Tab Template

Body Copy vs. No Body Copy:

Our high speed tabbing equipment has heated rollers.

In some cases, when tabs with body copy are run through the heated rollers, the

ink bubbles or even gets lifted off the sheet.

Use heat-resistant and wax -free inks

and varnishes when supplying printed tabs to help eliminate this problem.

Porous stocks are optimum for Mylar

jobs because air has the ability to escape into the paper. Uncoated, 110# index

stock is the most commonly used. Coated stocks, along with heavy ink coverage,

can trap air and create bubbles that can distort the readability of the tab

Tabs without body copy have no problems.

We can do tabs with body copy on our equipment that do not have heated rollers; however, the

speeds are slower.

This

is a sample of a tab with body copy. This

is a sample of a tab with body copy.

This

is a sample of a tab without body copy. This

is a sample of a tab without body copy.

Tab Ink:

The type of ink used and the amount of coverage affect

the ability of the laminate to adhere properly. The laminate is heated and applied

to the sheet. The laminate may not adhere properly if the ink is not wax-free or the

coverage is too heavy. There is a special cold laminate for this application.

Consider this when planning tabs and if you

have any concerns, send us a sample and we will test it. It is better to locate a

problem before rather than after printing a job.

|